Portfolio

At Meyers, we live for the possibilities created by product packaging, labels, and retail displays. Bringing brands to life, telling their stories, and spurring new ideas, is our passion. And the opportunity to create a tangible part of your brand – the part consumers see and feel before opening the package – is something we cherish.

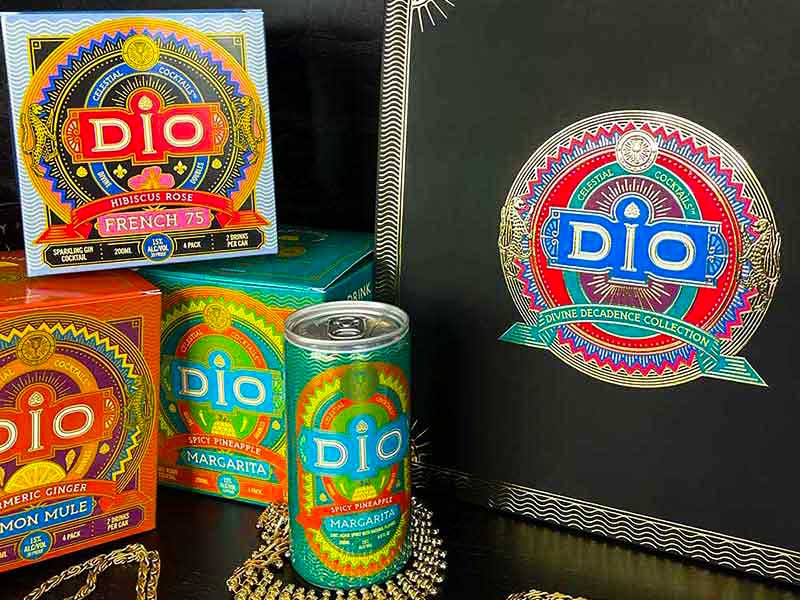

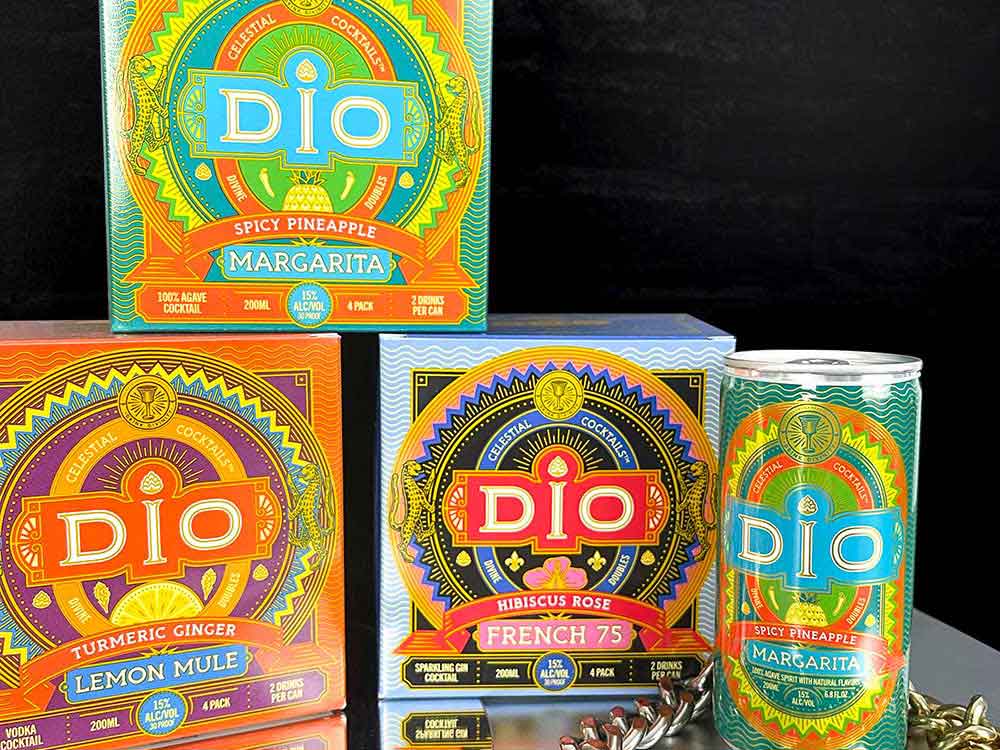

Dio

Dio Orleans

Orleans Teton Waters Ranch

Teton Waters Ranch Aveda

Aveda Pop Smith

Pop Smith Function of Beauty

Function of Beauty Kikkoman

Kikkoman Future Society

Future Society Cerebelly

Cerebelly Back Porch Pots

Back Porch Pots Amayu

Amayu Dio

Dio Ulta Beauty

Ulta Beauty Crest

Crest G&H Orthodontics

G&H Orthodontics Disney

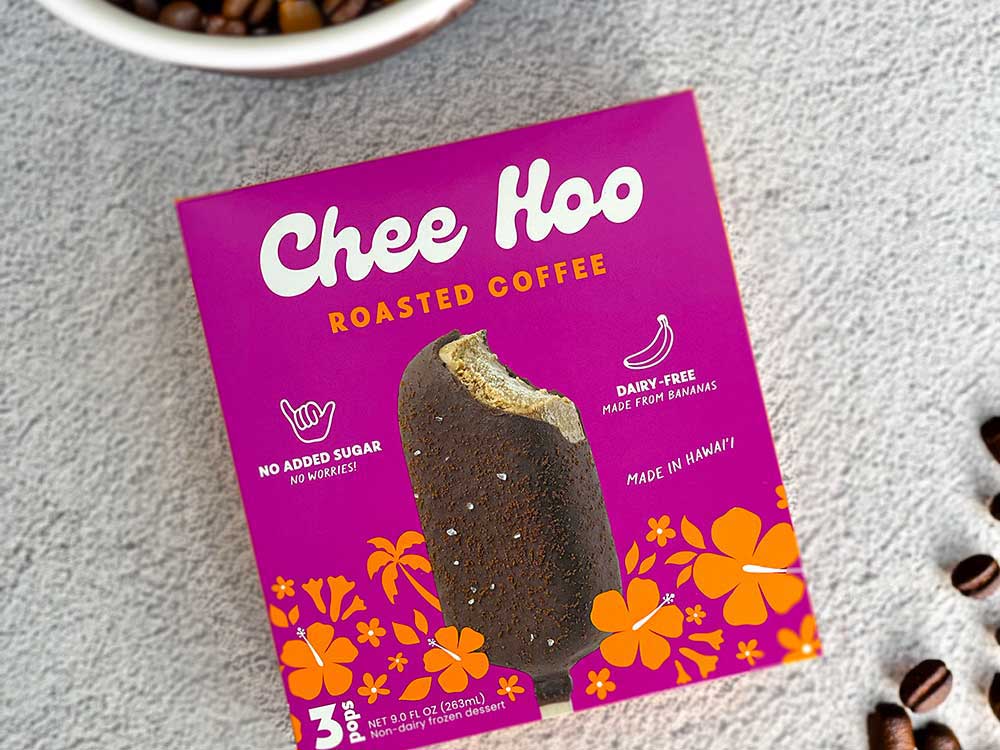

Disney Chee Hoo

Chee Hoo NovaFerrum

NovaFerrum Pamos

Pamos Core Ritual

Core Ritual Free People

Free People Liddle Me

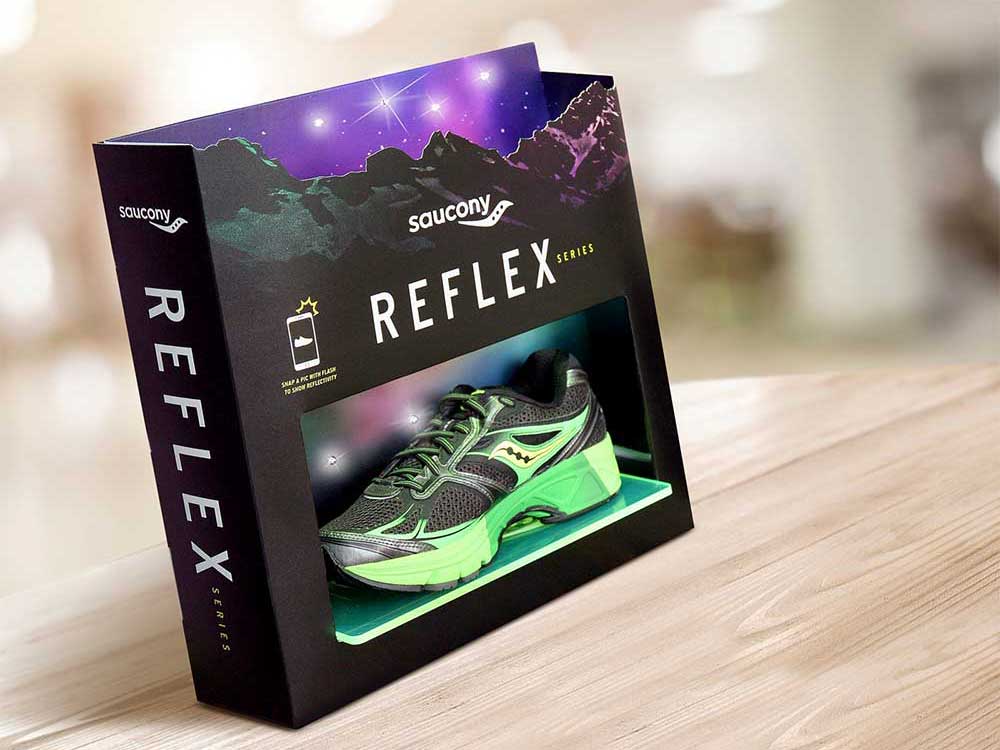

Liddle Me Saucony

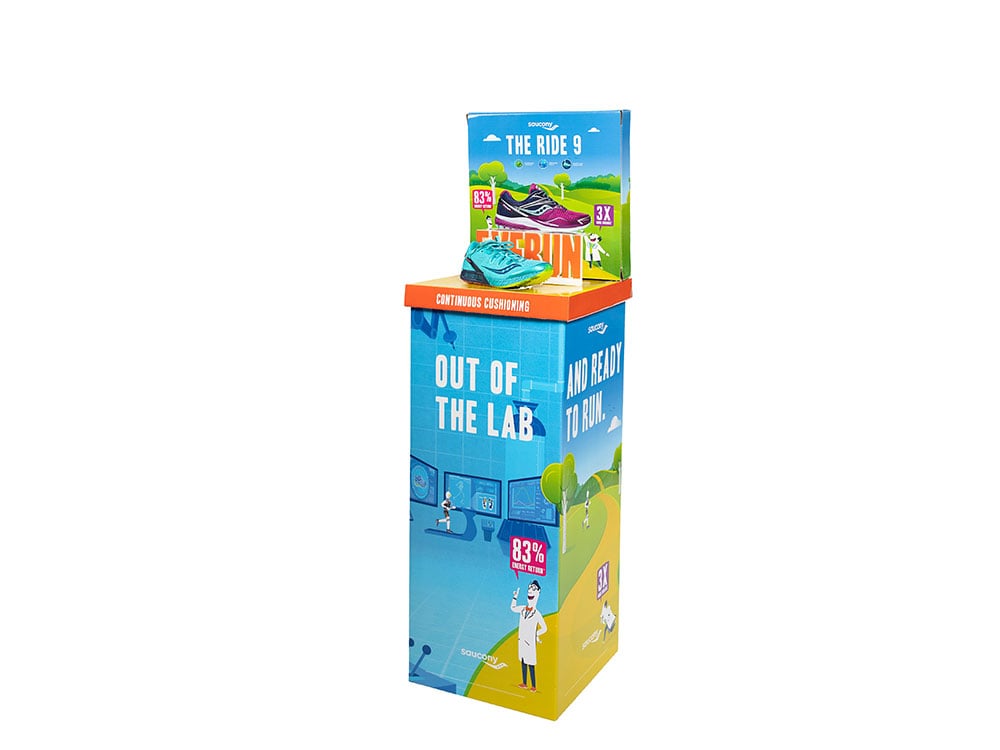

Saucony Julia’s Table

Julia’s Table Core Ritual

Core Ritual Future Society

Future Society Aveda

Aveda Hormel

Hormel Ulta Beauty

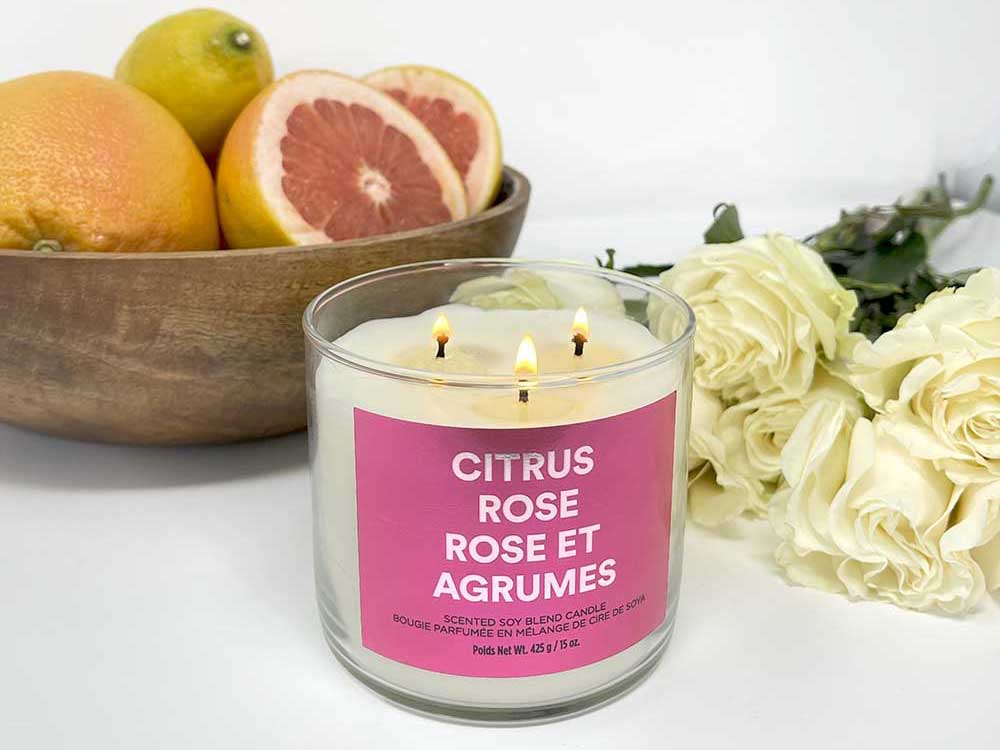

Ulta Beauty White Barn: Bath & Bodyworks

White Barn: Bath & Bodyworks Amayu

Amayu Verizon

Verizon Future Society

Future Society Cerebelly

Cerebelly Core Ritual

Core Ritual Free People

Free People Ulta Beauty

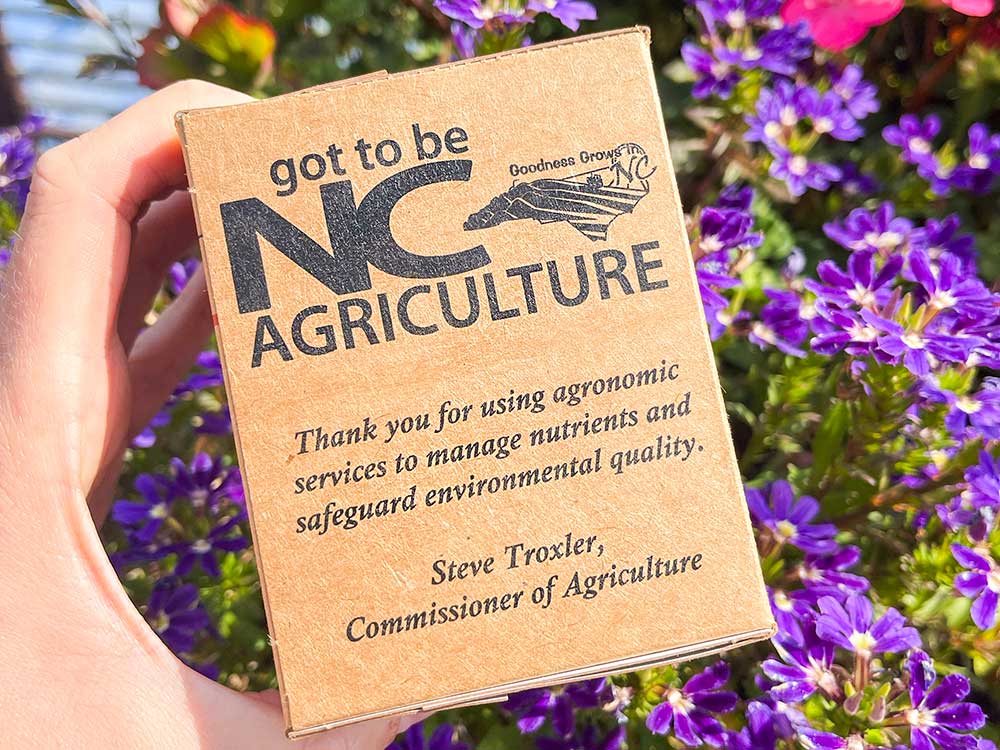

Ulta Beauty NC Agriculture

NC Agriculture Clariol

Clariol Pura- Lafco

Pura- Lafco Intelligent Nutrients

Intelligent Nutrients Meyers Promo Boxes

Meyers Promo Boxes Bach

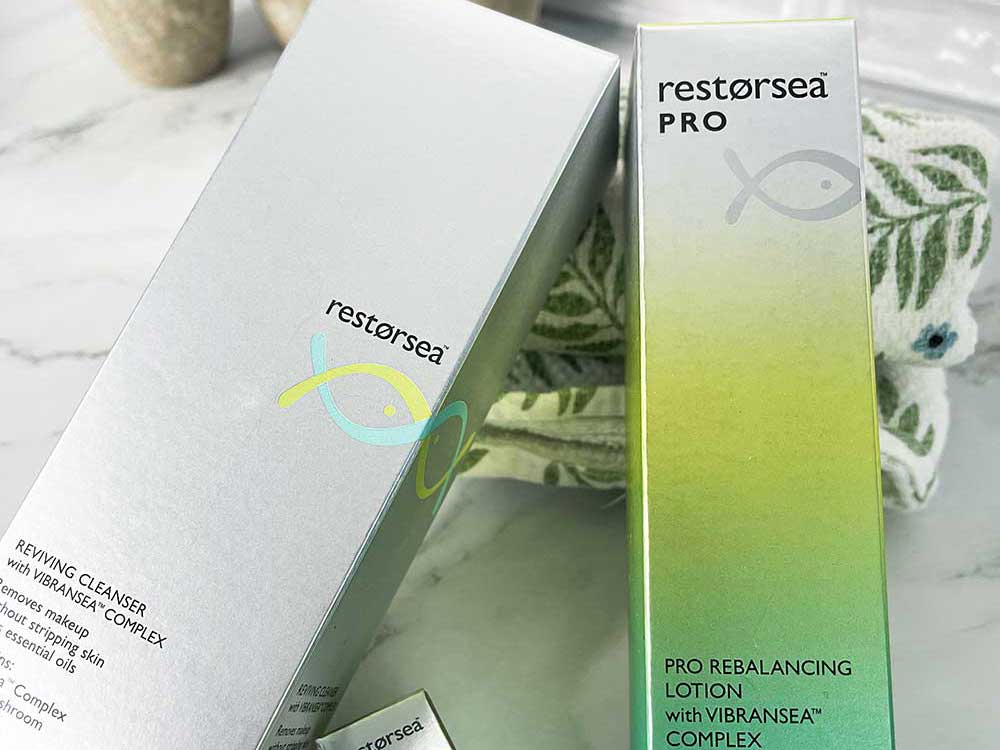

Bach RestoreSEA

RestoreSEA Pura-Antica Farmacista

Pura-Antica Farmacista Times

Times Ulta Beauty

Ulta Beauty Chee Hoo

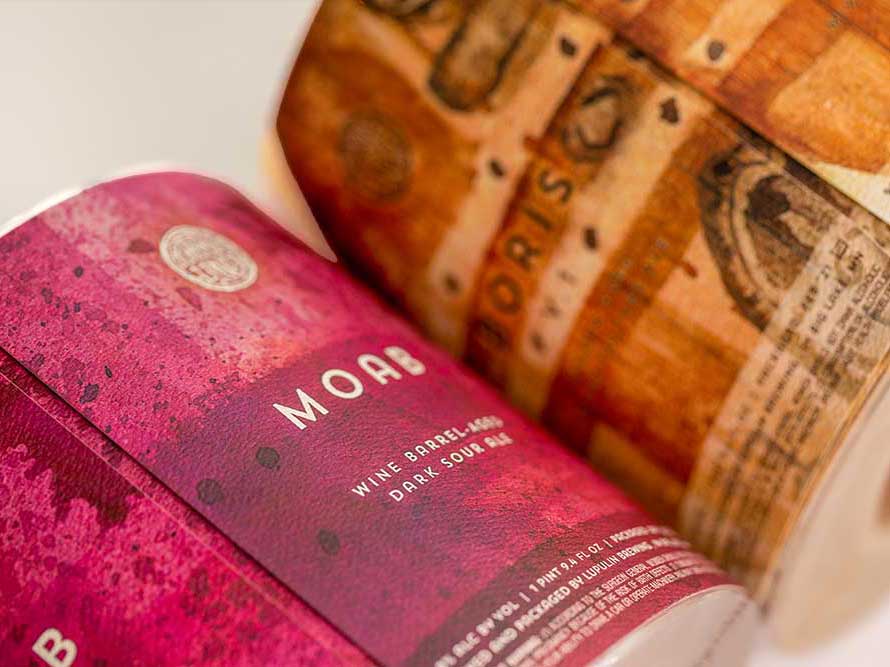

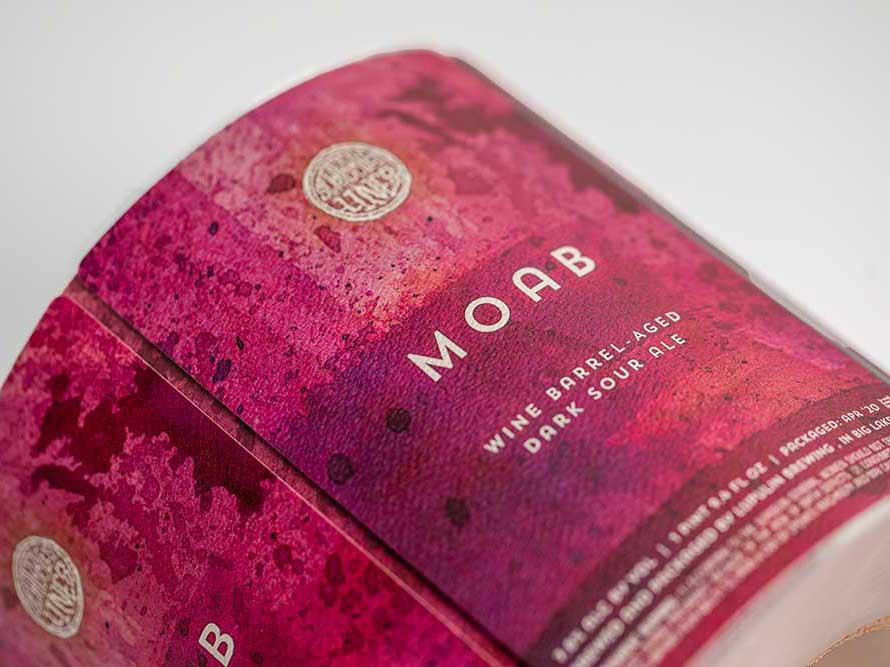

Chee Hoo BlackStack and Lupulin Brewing

BlackStack and Lupulin Brewing Lupulin Brewing Beer Labels

Lupulin Brewing Beer Labels Coupons

Coupons Amayu

Amayu Ulta Beauty

Ulta Beauty Free People

Free People Mama Natures

Mama Natures Dio

Dio Ritz Crackers

Ritz Crackers Nova Ferrum Supplement Packaging

Nova Ferrum Supplement Packaging Amour Vines

Amour Vines Cerebelly

Cerebelly Dots

Dots Lupulin Brewing

Lupulin Brewing NovaFerrum

NovaFerrum Bearsville

Bearsville Pamos

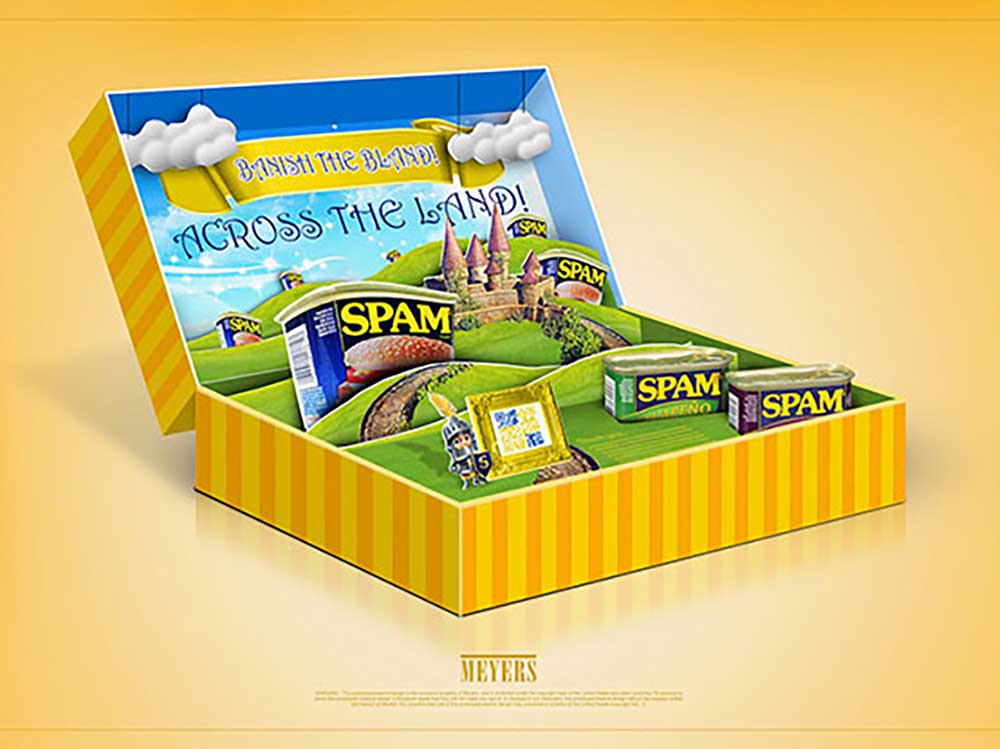

Pamos Spam

Spam Sense

Sense Cerebelly

Cerebelly Orleans

Orleans Dio

Dio Samsung

Samsung Pura- Illume

Pura- Illume Ulta Beauty

Ulta Beauty Petit Pot

Petit Pot Times

Times Free People

Free People Bearsville

Bearsville Future Society

Future Society Live Local Organic Farms Sustainable Food Packaging

Live Local Organic Farms Sustainable Food Packaging Saucony

Saucony NovaFerrum

NovaFerrum Sweet Spot Labs

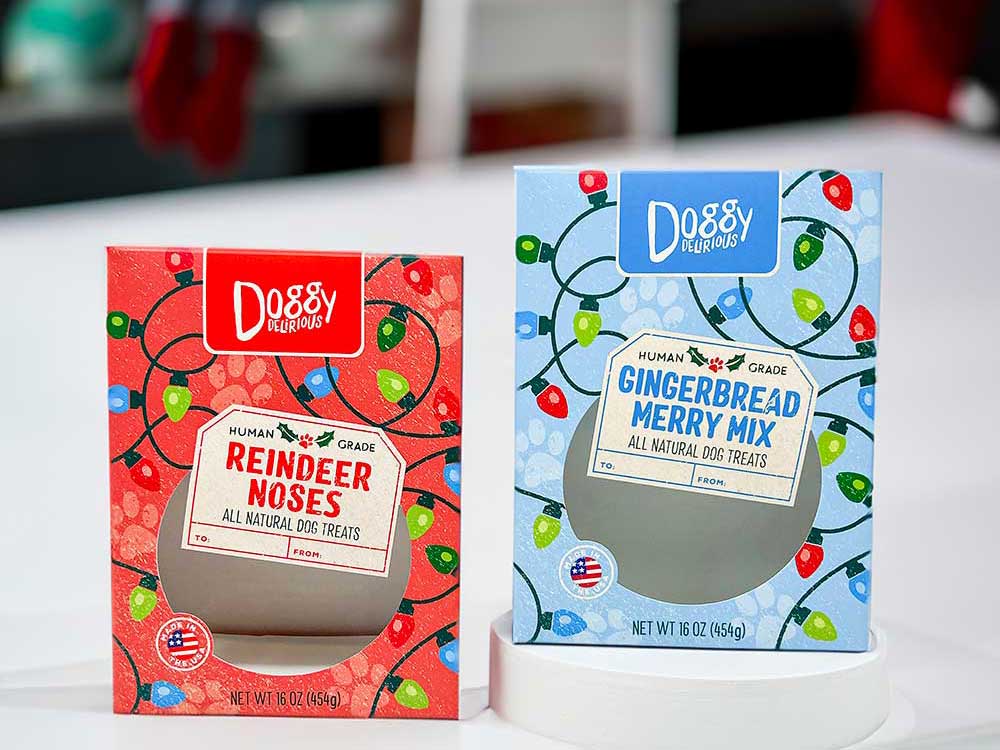

Sweet Spot Labs Doggy Delirious

Doggy Delirious Thymes

Thymes Petit Pots

Petit Pots Cerebelly

Cerebelly G&H Orthodontics

G&H Orthodontics Core Ritual

Core Ritual Liddle Me

Liddle Me Free People

Free People Ulta Beauty

Ulta Beauty

Ulta Beauty

Ulta Beauty NovaFerrum

NovaFerrum Core Ritual

Core Ritual Rae Wellness

Rae Wellness Orleans

Orleans Cracker Jacks

Cracker Jacks Lew’s

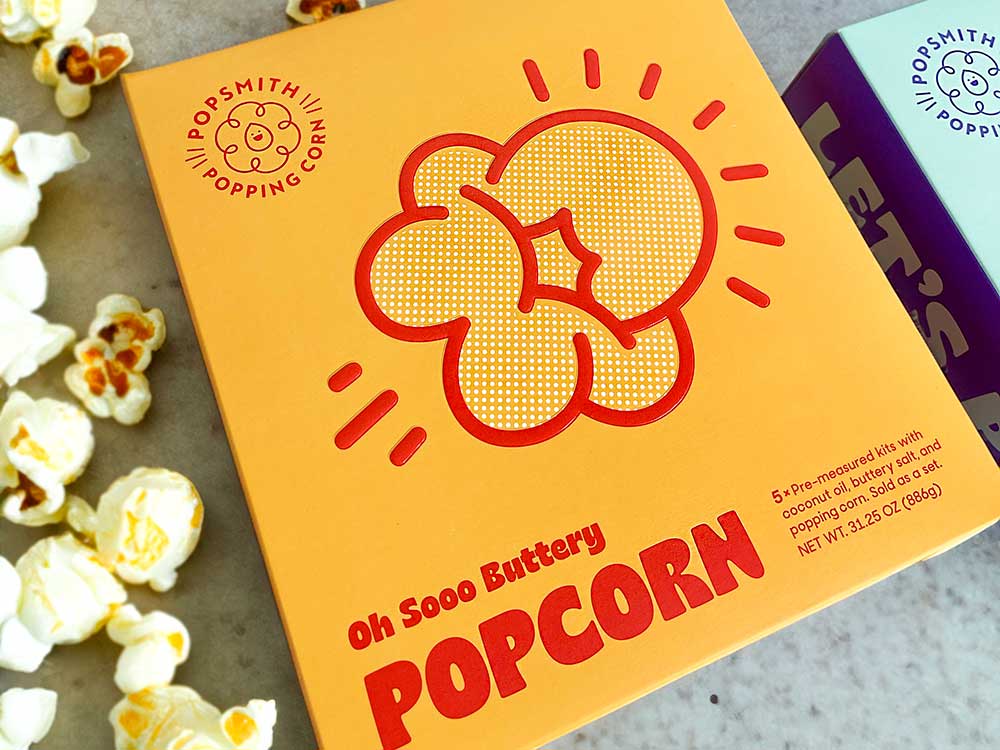

Lew’s Pop Smith

Pop Smith Cerebelly

Cerebelly Teton Waters Ranch

Teton Waters Ranch Levi’s

Levi’s Trident

Trident Future Society

Future Society Cerebelly

Cerebelly Hormel

Hormel Wet Noses

Wet Noses Garmin

Garmin Bach

Bach Ted’s

Ted’s Pura-capri blue

Pura-capri blue Budweiser

Budweiser Core Ritual

Core Ritual Pop Smith

Pop Smith Cerebelly

Cerebelly Core Ritual

Core Ritual Doritos

Doritos Chee Hoo

Chee Hoo NovaFerrum

NovaFerrum Core Ritual

Core Ritual Lowrance

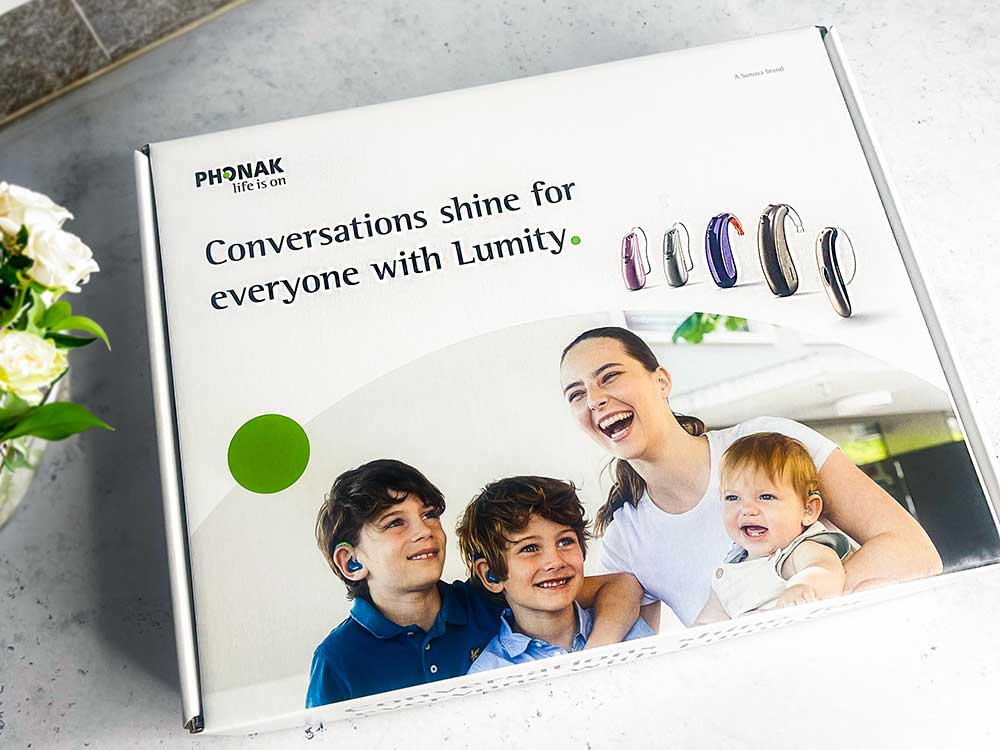

Lowrance Phonak

Phonak